Rotary mills HV.

Rotary mills are intended for grinding of relatively mild, brittle, less abrasive materials such as grain for feeding domestic animals, dried vegetables, peat, dry yeast, salts, microfertilisers, and car waste catalysts into the product with particles between 0.2-2 mm.

Prerequisites for the initial material: hardeness of up to 600 kg / cm2, size of pieces below 10-15 mm, content of moisture of up to 5 %.

The central part of the rotary mill is a rotor with several plates and a built-in sieve.

The fineness of the product depends on the sieve's apertures and the speed of the rotor's rotation.

| HV-1A | HV-2 | HV-3 | |

| Max. capacity, kg / h | 250 | 500 | 800 |

| Power of electric motor, kW | 4,0 | 5,5 | 7,5 |

| Volume of the hooper, dm3 | 50 | 60 | 60 |

| Diameter / width of sieve, mm | 320 / 62 | 500 / 62 | 500 / 120 |

| Dimensions, mm: | |||

| - length | 670 | 800 | 950 |

| - width | 580 | 600 | 600 |

| - height | 780 | 1050 | 1050 |

| Max. weight, kg | 55 | 70 | 95 |

| Sound level (at distance 1 m), dB | 80 | 85 | 90 |

The mill can be supplied with different sieves of varying apertures 2.0 - 8.0 mm.

Mills can also be produced for performance testing of small batches of material with pieces of up to 50mm.

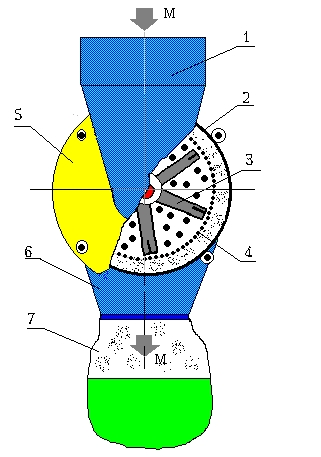

1. Feeding hopper

2. Housing 3. Rotor

4. Sieve 5. Cover

6. Unloading channel

7. Big - bag

M - material

Pictures: