|

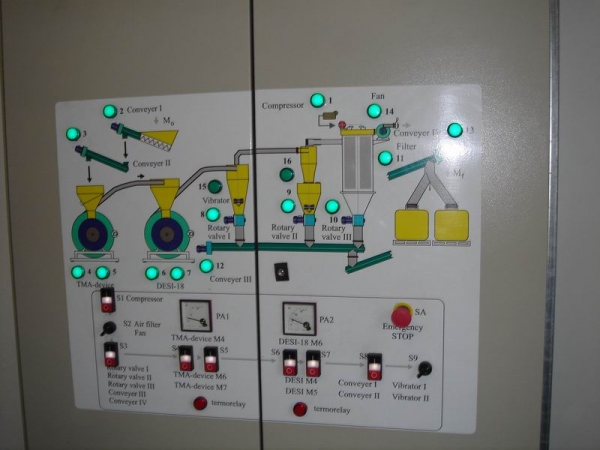

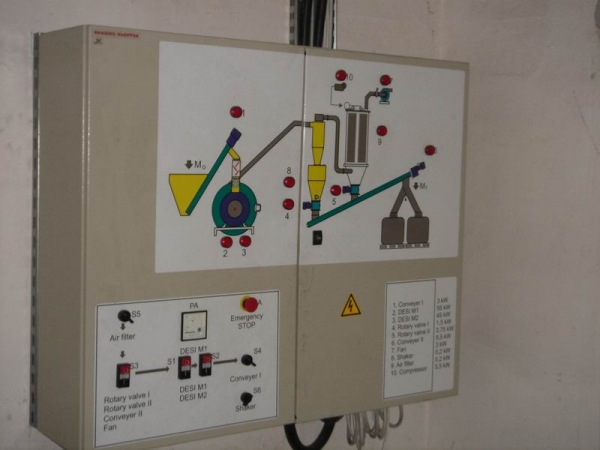

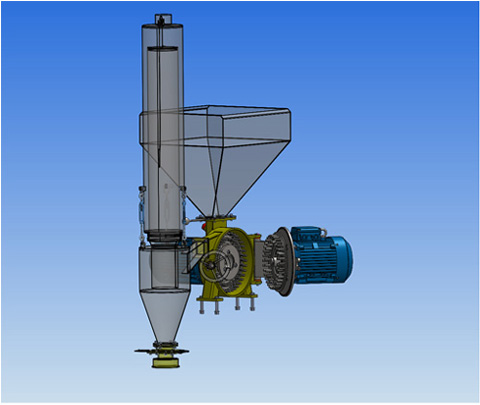

Disintegrator is a multifunctional mill, intended for fine grinding of dry, relatively less abrasive powdered or granulated materials ( with particles below 10 - 20 mm ). For some materials and systems mechano-activation is also available. In the disintegrator it is possible to effectively grind different dry biological, organic, inorganic and metallic materials. It is also possible to treat liquids: solutions, emulsions and suspensions. Grinding in the disintegrator is performed by several, usually 3-7 impacts at high speed of up to 100-200 m/s. The speed is increased as the particles move from the center of the rotors to the periphery. The central part of the disintegrator consists of two rotors which revolve in opposite directions, with several concentrically placed rows of impact elements with different design. We design, develop and produce industrial disintegrators and technological lines which differ by performance, constructions, modes of operation and productivity. We also design and produce disintegrators for research works and testing. The fineness of the ground product depends on the properties of the iniatial material, the size of the particles, the model of the disintegrator, and the grinding regimes. The fineness of the material ground in the disintegrator could reach from several microns to hundreds of microns. When using our grinding lines with built-in or external classifiers it is possible to obtain powders with 97 - 99 % fractions below 60 - 100 mkm while directing coarse fraction to the disintegrator for further grinding. In addition to the disintegrators and mills, we offer grinding technologies and design industrial lines. We are able to incorporate equipment from other manufactures. We also offer our expertise in the installation and fine-tuning of the lines. |

| |

Disintegrators DESI.

Disintegrators DESI.