Disintegrators DESI-16 and DESI-16C.

Disintegrators are used for grinding dry granulated and powdered unorganic materials such as salts, microfertilizers, catalists, fillers, as well as organic (resins) and biological (sugar, spices, dried berries and vegetables, coffee beans and so on ) materials into powders with particles' size between 0.05-0.2mm.

Prerequisits for the initial material: hardness by Mohs up to 5-6, size of particles below 10 mm, moisture below 6 %.

Disintegrator DESI-16C is also used for the preparation of various suspensions.

The grinding units built on the basis of our Disintegrators include feeding, dust removing, product transporting, offloading of the ground product and the necessary electrical equipment.

| DESI-16 | DESI-16С | |

| Max. capacity, kg/h | 200-600 | 200-600 |

| Installed power, kW | 6.0 or 9.5 | 6.0 or 9.5 |

| Diameter of working chamber, mm | 340 | 600 |

| Diameter of rotors, mm | 300 | 335 |

| Overall number of rows with impact elements | 3-5 | 3-7 |

| Frequency of rotors' rotation, Hz | 50 | 50 / 50 + 20-72 |

| Volume of feeding hopper, dm3 | 40 | 40 |

| Max. dimensions, mm: | ||

| - length | 780 | 800 |

| - width | 920 | 950 |

| - height | 1870 | 1870 |

| Max. weight, kg | 160 | 180 |

| Sound level (at distance 1 m), dB | 100 | 100 |

Standard delivery of Disintegrator DESI-16 includes: a feeding hopper with a slider-valve, a frame, a cyclone, an air bag filter, and a control board.

Standard delivery of Disintegrator DESI-16C includes: a feeding hopper with slider-valve, a frame, an air bag filter, and a control board.

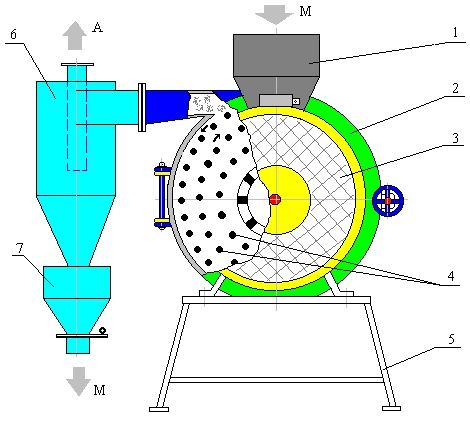

DESI-16

1. Loading hopper with a slider-valve

2. Case

3. Electric motor

4. Set of rotors

5. Frame

6. Cyclone

7. Hopper of the cyclone

M - initial and ground material

C - air (in an air bag filter)

Pictures: