Drum mixers 4C4 and 4C6.

Drum mixers are intended for the preparation of homogeneous mixtures consisting of the multiple granulated or powdered materials such as fertilizers, building mixtures and so on. They can also be used for the averaging of the composition of batches of materials.

Prerequisites for the mixing material: particles' size of up to 20 mm, content of moisture up to 5 %.

Drum mixer has a horizontal rotation shaft, positioned at an angle to the axe of the drum ( housing ). Within the housing there are plates in order to involve the material in the rotation and to direct the material further and along the housing.

The components are loaded into the mixer through one of the hatches. After obtaining a homogeneous composition of the mixture, it is offloaded from the mixer through one of the hatches. The process may be repeated on another batch of material.

Mixing time is between 10-20 min. The non-uniformity of the prepared mixtures does not exceed 2-3 %.

| 4C4 | 4C6 | |

| Volume of the drum, dm3 | 250 | 400 |

| Power of electric motor, kW | 2.2 | 2.2-3.0 |

| Speed of drum's rotation, rpm | 25 or 40 | 25 or 40 |

| Max. dimensions, mm: | ||

| - length | 1400 | 1790 |

| - width | 1140 | 1400 |

| - height | 1130 | 1260 |

| Max. weight, kg | 250 | 450 |

| Sound level (at distance 1 m), dB | 70 | 80 |

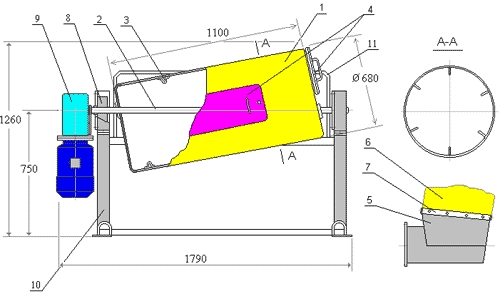

Batch mixer 4C6

1. Housing 2. Shaft 3. Hook 4. Hatch 5. Funnel 6. Connecting channel

7. Fixator 8. Bearing 9. Motor – reductor 10. Frame 11. Protector

Pictures: