Dispergators 3Y.

Dispergators are used for the preparation of different fine stable suspensions such as catalists and pastes such as phosphogips and black oil treatment wastes.

Prerequsits for the initial material: viscosity up to 250 cSt, temperature up to 80 C, the content of solid phases up to 75 %, and the particles' size up to 8 mm.

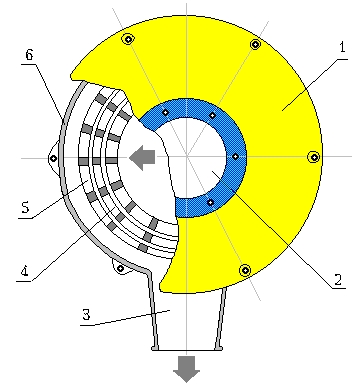

The central part of a dispergator consists of a rotor and a stator with a few concentrically placed rows with working elements. The material in the dispergator is treated by combined hydrodynamic, shift and cavitation forces.

The fineness of the solid phases in the treated material is between 10-50 mkm.

| 3Y8 G | 3Y8 BM | 3Y1B | |

| Max. capacity, kg/h | 500 | 1 500 | 10 000 |

| Power of electric motor, kW | 11 | 30 | 110 |

| Frequency of rotors' rotation, Hz | 50 | 50 | 50 |

| Diameter of rotor, mm | 300 | 400 | 634 |

| Max. dimensions, mm: | |||

| - length | 1300 | 1500 | 2860 |

| - width | 550 | 650 | 980 |

| - height | 650 | 700 | 1000 |

| Max. weight, kg | 280 | 450 | 2200 |

| Sound level (at distance 1 m), dB | 80 | 90 | 110 |

Dispergator 3Y8

1. Cover 2. Feeding channel

3. Unloading channel 4. Stator

5. Rotor 6. Housing

Pictures: