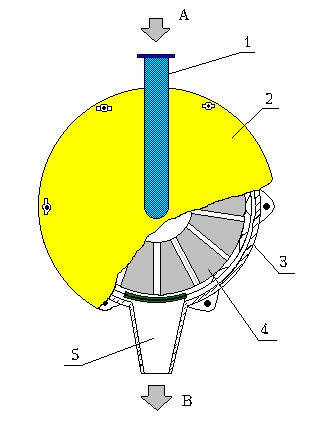

Emulsifier ERV-2.

Emulsifier is used for the preparation of stable liquid foodstuffs such as: mayonnaise, dressings, and ketchup.

Prequisits for the iniatial material: viscosity up to 120 cSt, size of particles ( aglomerates ) of solid phases up to 1 mm.

The central part of the emulsifier ER consists of a stator (three blocks on the cover of the emulsifier) and a rotor with a few radial channels which are periodically opened and closed at the rotor's rotation. On periphery the rotor has a girdle.

Pre-mixed material is fed into the emulsifier and subjected to the combined pulsating, shifting and cavitation forces which diminish the size of the liquid and solid phases which leads to the material's dispergation and homogenization.

The emulsifier is usually used together with a mixer for a preliminary mixing of all components. If a finer product is neccesary, the process of emulsification can be repeated by directing the product into the mixer.

| Max. capacity, kg/h | 200-400 |

| Max. viscosity, cSt | 120 |

| Electric motor power, kW | 4,0 - 11,0 |

| Frequency of rotor rotation, Hz | 25 or 50 |

| Diameter of the rotor, mm | 260 |

| Max. dimensions, mm: | |

| - length | 820 |

| - width | 310 |

| - height | 510 |

| Max. weight, kg | 80 |

| Sound level (at distance 1 m), dB | 70 |

Figure

1. Loading channel

2. Cover with blocks

3. Case 4. Rotor

5. Unloading channel

A - Initial mixture

B - Prepared product

Pictures: