Emulsifier ER.

Emulsifiers ER are used mainly for the preparation of stable water & black oil emulsions. ER-3A is also used for the preparation of paints, glues and etc.

Prerequisits for the treated material: viscosity of up to 180 cSt, temperature of up to 120 C, and the size of the solid phases particles of up to 1 mm.

The pressure in the working chamber should be limited to 0.7-1.4 mPa. The optimum water content in a fuel black oil & water emulsion is between 15-20 % while the maximum water content is 35 %.

Due to a high degree of phase disintegration, emulsion's homogenisation and a more complete combustion of the fuel mixture, emulsifiers ER allow:

- a decrease in the fuel expenditure by 4-8 %;

- a decrease in the quantity of CO and soot in the exhausted gases;

- a decrease of furnaces wear by in 1.2-1.8 times;

- to achieve an average particle size in emulsions of 1.5-3.0 mkm;

- to achieve a stability of fuel emulsions for 30-60 days.

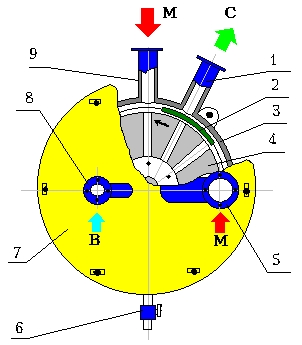

The central part of the emulsifier ER consists of a stator (three blocks on the cover of the emulsifier) and a rotor with a few radial channels which are periodically opened and closed at rotor's rotation. On periphery the rotor has a girdle.

The components of the emulsion are fed under pressure into a working chamber of the emulsifier. The mix is forced by the combined pulsating, shifting and cavitation forces to disintegrate and homogenise. Part of the black oil of the fuel emulsion could also be fed straight into the periphery of the rotor, where it could be mixed with the rest of the emulsion.

| ER-3A | ER-4 | ER-5 | |

| Max. capacity, t/h | 3 / 5 | 18 | 30 |

| Power of electric motor, kW | 4.0 / 5.5 (7.5) | 30 | 55 |

| Diameter of rotor, mm | 260 | 340 | 420 |

| Frequency of rotors rotation, Hz | 25 (50) | 25 | 16 (25) |

| Max. dimensions, mm: | |||

| - length | 1165 | 2000 | 2066 |

| - width | 400 | 600 | 670 |

| - height | 592 | 580 | 920 |

| Max. weight, kg | 225 | 600 | 1100 |

| Sound level (at distance 1 m), dB | 80 | 85 | 90 |

Figure

1. Unloading channel

2. Block 3. Case 4. Rotor

5, 9. Black oil feeding channel

6. Tap 7. Cover

8. Water feeding channel

M - Black oil B - Water C - Emulsion

Pictures: